U-shaped glass curtain wall is popular with owners

and the building designer's favor

because there are a lot of features.

For example

Low heat transfer coefficient

Good thermal insulation performance, small color difference

The construction of the installation is simple and convenient.

Good fire protection performance, save money and environmental protection

... Wait a minute

01.

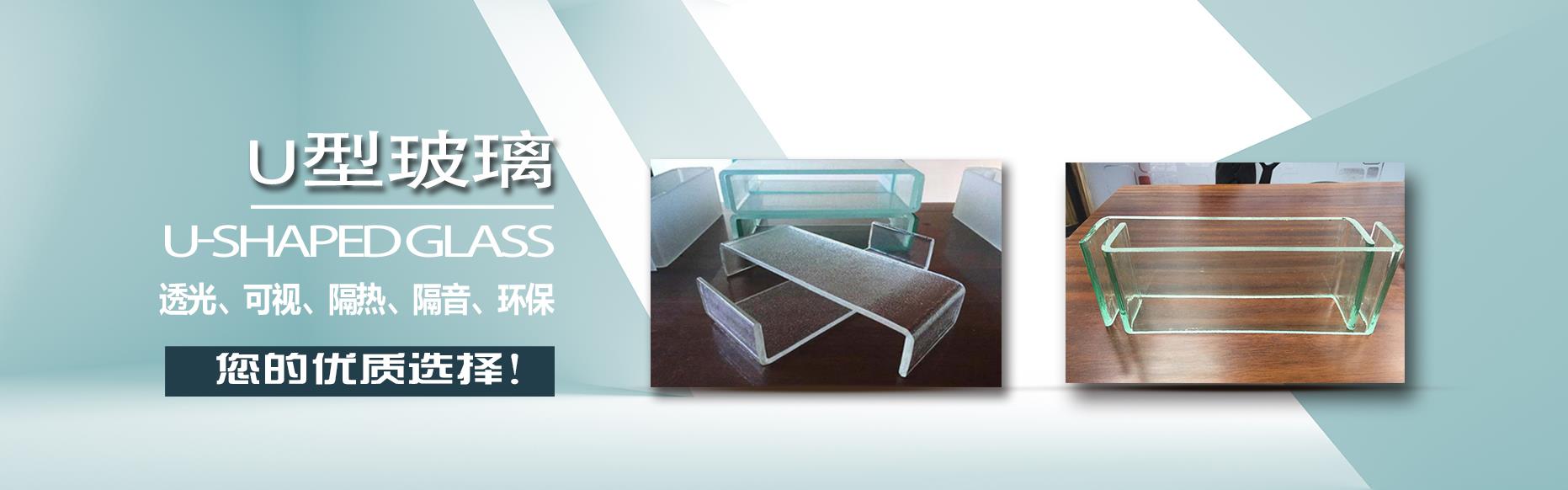

Introduction to U-shaped glass

Construction U-shaped glass (also known as slot-shaped glass) is a first-press delay molding method of continuous production, because its cross-section is "U"-type, so named. It is a novel architectural profile glass. U-shaped glass variety, with good light transmission but not perspective characteristics, thermal insulation performance and sound insulation performance is good, than ordinary flat glass mechanical strength is high, simple construction, has a unique architectural and decorative effect, can save a lot of light metal profiles, a wide range of uses.

Products by China's glass quality supervision and inspection center in accordance with the building materials industry standard JC/T867-2000 "Construction U-shaped glass" inspection qualified, the technical indicators by reference to the German industrial standards DIN1249 and 1055 standards.

Products have been included in Yunnan Province in February 2011 new wall materials product catalog.

02.

Scope of application

Can be used in airports, stations, stadiums, factories, office buildings, hotels, residential, greenhouse and other industrial and civil buildings non-weighted internal and external walls, partitions and roofs.

03.Reference Standards and Atlas

Construction material industry standard JC/T 867-2000 "U-shaped glass for construction"

German industrial standards DIN1055 and DIN1249

Architectural Standard Design Atlas 06J505-1 Exterior Renovation (I))

04.U glass classification

By color classification: colorless, spray color, film color. Commonly colorless.

By surface status: pressure pattern, smooth, fine pattern. Common pressure patterns.

By strength classification: ordinary, tempered, film, reinforced film and fill insulation layer.

05.Architectural Design Applications

U-shaped glass as a wall material can be used in the building walls, exterior walls, partitions and other parts. Exterior walls are generally used in multi-storey buildings, the height of the glass depends on the air load, the height of the glass distance and the way the glass is connected. Data on German industrial standards DIN-1249 and DIN-18056 are provided in this special issue (Schedule I) for the design of multi-storey and high-rise buildings. U-shaped glass exterior wall node diagram in the building standard design atlas 06J505-1 "exterior decoration (i)" and this special issue are specifically described.

U-shaped glass is a non-combustible material. By the fire building materials quality supervision and inspection center test, fire resistance limit of 0.75h (single row, 6mm thick). If there are special requirements, the design or fire prevention measures should be carried out in accordance with the relevant specifications.

U-shaped glass can be single-layer, double-layer installation, installation with ventilation seams or no ventilation seams can be. This special issue provides only two combinations of single-row wing facing outward (or inner) and two-row wings arranged in pairs at the seams, which should be noted when other combinations are used.

How to install

Pre-installation preparation: The contractor must understand the relevant regulations for the installation of U-shaped glass, be familiar with the basic methods of U-glass installation, and carry out short-term training work for operators. Sign the "Safety Assurance Agreement" and write into the "Engineering Contract" before entering the construction site.

Installation process: before entering the construction site, combined with the actual formulation of "device technology", and the basic requirements of the installation process to the hands of each operator, require familiar reading and will operate, if necessary, organize ground training, especially safety operating norms, no one may violate.

The basic requirements of the device: usually with special aluminum profile border data, can also be based on the user's requirements with stainless steel border or ferrous metal data, when the use of metal-type steel to have outstanding anti-corrosion and rust treatment. The border information shall be firmly fixed with the wall or the construction of the hole, and shall be not less than 2 fixed points per extension meter.

Installation height calculation: see drawing (see profile glass mounting altimed). U-shaped glass is installed in the four-box hole in the transparent wall, the length of the glass for the box hole's height minus 25 to 30mm, the width can not consider the number of building modules, because U-shaped glass can be arbitrarily cut. 0 to 8m scaffolding. High-rise installation generally uses the hanging basket method, safe, fast, practical and convenient.

09.

Installation process

Secure the aluminum profile frame with stainless steel bolts or rivets on the building. Carefully scrub the inside of the U-shaped glass and insert it into the frame.

The stable cushioning plastic parts are cut into the corresponding lengthand and placed within a fixed frame.

When the U-shaped glass is installed to the back of the piece, the width margin of the hole can not be loaded into the whole glass, the U-shaped glass can be trimmed along the length direction to meet the remaining width. The cut-out U-shaped glass should be installed first into the border and then installed as required by Article 5.

When installing the next three U-shaped glass, two pieces of glass should be entered into the frame before the third glass seal is installed.

Adjust the temperature telescopic gap between U-shaped glass, especially in areas with large annual temperature differences.

U-shaped glass height is not greater than 5m, the permissible deviation of the verticality of the frame is 5mm, and when the horizontal width of The U-shaped glass is greater than 2m, the allowable deviation of the horizontal component horizontality is 3mm.U-shaped glassAt a height not greater than 6m, the permissible deviation of the component's cross-deflection is less than 8mm.

Cleaning glass: When one wall is finished, the cleaning surface leaves traces.

In the gap between the border and the glass, the elastic pad is stuffed, and the pad must not be less than 12mm in contact with the glass and the frame.

In the seams of borders and glass, glass and glass, borders and architectural structures, fill in glass gel elastic sealing material (or silicone seal).

The load on the frame should be passed directly to the building, and the U-shaped glass wall is a non-load-bearing wall that is unforceable.

When installing the glass, wipe the inner surface clean, after installation, then wipe the dirt on the outer surface clean.

10.

Transport

In general, cars are transported from the factory to the site. Due to the characteristics of the construction site, it is difficult to find flat land and warehouse, but must maintain the safety and cleanliness of U-shaped glass, it is recommended to take cleaning measures.

11.

Unloading

By the U-shaped glass manufacturer with a car crane loading vehicle, by the construction party responsible for unloading the vehicle. In order to avoid the problems of damage, damage to packaging, and uneven site due to not knowing the method of unloading, it is recommended to standardize the unloading method.

In the case of wind load, usually to calculate the maximum use length of U-shaped glass to determine its wind pressure strength: L-U-glass to large use length, md-U-glass bending stress, N/mm2WF1-U-glass The anti-bending modulus of the wing (see table 13.2), cm3P - wind load standard value, kN/m2A-U-glass bottom width, m13.2 U-shaped glass of different specifications of anti-bending mold.

Anti-bending modal values for different mounting methods

When the wing is oriented towards the force, the anti-bending modulus Wst of the soleplate is used.

When the base plate is oriented towards the force, the wing's anti-bending modulus WF1 is used.

When the U-shaped glass is installed in front of an inverse, the comprehensive value of the comprehensive anti-bending modulus is used.

In the cold winter, due to the large indoor temperature difference, the glass towards the indoor side of the easy condensate. With single row and double row U-shaped glass as the enclosure structure of the building, when the outdoor temperature is low and the indoor temperature is 20 degrees C, the formation of condensate is associated with outdoor temperature and indoor wet 12.

Insulation performance

Double-layered U-shaped glass, with different filling materials, its heat transfer coefficient can reach 2.8 to 1.84W / (m2? K). In Germany's DIN18032 safety standard, U-glass is classified as safety glass (china's relevant standards have not yet been included in the safety glass), can be used for ball stadiums and roof lighting roof. By strength calculation, U-shaped glass is 4.5 times safer than regular glass. U-shaped glass self-contained component type, after installation and flat glass under the same area conditions of strength, with the area formula: Amax -alpha (0.2t1.6 plus 0.8)/Wk calculation, the formula reflects the corresponding relationship between the glass area and the strength of the air load. U-shaped glass achieves the strength of the same area as the tempered glass, while the two-wing sealant bonding forms the overall safety of the glass (which is a safety glass in German industrial standard 1249-1055).

U-shaped glass vertical mounting facade

Related News

- Analysis of U-shaped glass in the market

- Signing the U-shaped glass project of Nanjing General shan Junior High School

- Performance and application of curved tempered glass

- Cause Analysis and Control of Stress Spot on Tempered Glass

- Hangzhou Xiangjie tells you how to install U-shaped glass

- Stained glass is gradually expanding in the construction market

- Energy-saving and environmental-friendly building curtain wall glass will become the new darling of the future market

- How refractory materials are used in U-shaped glass furnace

- What are the characteristics of wire U-shaped glass

- Toughened glass manufacturers share their little knowledge of laminated glass

- Matters needing attention for installation of frosted glass installation partition

- Scope of application of U-shaped glass fire resistance

- Frosted glass manufacturers tell you the necessity of establishing company compartment

- Briefing on the preparation work of the shaped glass edging machine

- Difference analysis of tempered glass

- Selection method of special-shaped glass mechanical parts

- Little knowledge about stained glass

- Frosted glass installation process

- Demystifying the difference between tempered glass and ordinary glass

- How to distinguish between ordinary glass and tempered glass