Stained glass is gradually expanding in the construction field

In recent years, high-rise constructions rising from the ground are gradually replacing the old low-rise high-rise buildings, becoming people's new day, office, social place. Replacing the original reinforced concrete exterior structure with glass curtain walls has become a distinctive feature of these constructions. From the practical point of view, the use of glass structure can effectively isolate the solar radiation, insist on the internal temperature of the building, and the appearance of the traditional building is also more fashionable and modern. After inquiries about well-known processing enterprises in the industry, it is known that there are many silk screen processing enterprises in the art and decorative glass processing field. This field has relatively low requirements on equipment skills and other aspects, and the profit margin is abundant, which makes many companies rush, and colored glazed glass has a wide range of application fields and market prospects.

Stained glassBecause of its excellent decorative function, it is widely used in the construction field, adding countless beautiful colors to the monotonous architectural style. In recent years, with the development of processing technology, screen printing has replaced the early decal process and has gradually become an indispensable processing link in the process of colored glazed glass processing.

In addition to screen printing, sintering is also an indispensable part of the process of colored glaze glass. The sintering of glass colored glaze is also called roasted flowers, and is generally carried out in a roasted flower furnace. The key to sintering glass glaze is to control the sintering temperature. The silk screen reminds that the color glaze ink is prepared with oily solvent and alkyd resin. The firing in the furnace will go through the following stages:

One stage: from room temperature to 120 ℃, preheating, no change in printing ink;

The second stage: from 250 ° ~ 500 ° C, heavy oil and resin are combusted and gasified;

The third stage: from 120 ° to 250 ° C, light oil evaporates and gasifies;

The fourth stage: from 500 ° ~ 580 ° C, the glass powder in the color glaze begins to melt, and the surface of the substrate glass also softens slightly;

The fifth stage: from 580 ° ~ 620 ℃, the glass glaze powder is completely melted, and the pigment powder is also melted into it. At this time, the surface of the glass body is also completely softened, and the color glaze and glass are integrated To complete the transfer and sintering of the glaze, and then slowly reduce to room temperature.

0010010 nbsp; 0010010 nbsp; 0010010 nbsp; 0010010 nbsp; In addition, compared to traditional baked glass, stained glass performs better in all aspects . For example, environmental protection, productivity, etc. Especially in terms of color expression, the glaze of colored glazed glass is integrated with the glass itself and never fades; while the painted glass only uses ink to attach the ink to the surface of the glass using physical methods Stained glass is not the same.

More and more cities have begun to use tempered glass as the outer curtain wall, and this mall has also entered a situation of supply and demand. In order to seek characteristics and express the harmonious beauty of the construction, stained glass also followed the tide of the glass shopping mall to the historical stage of construction and decoration.

Related News

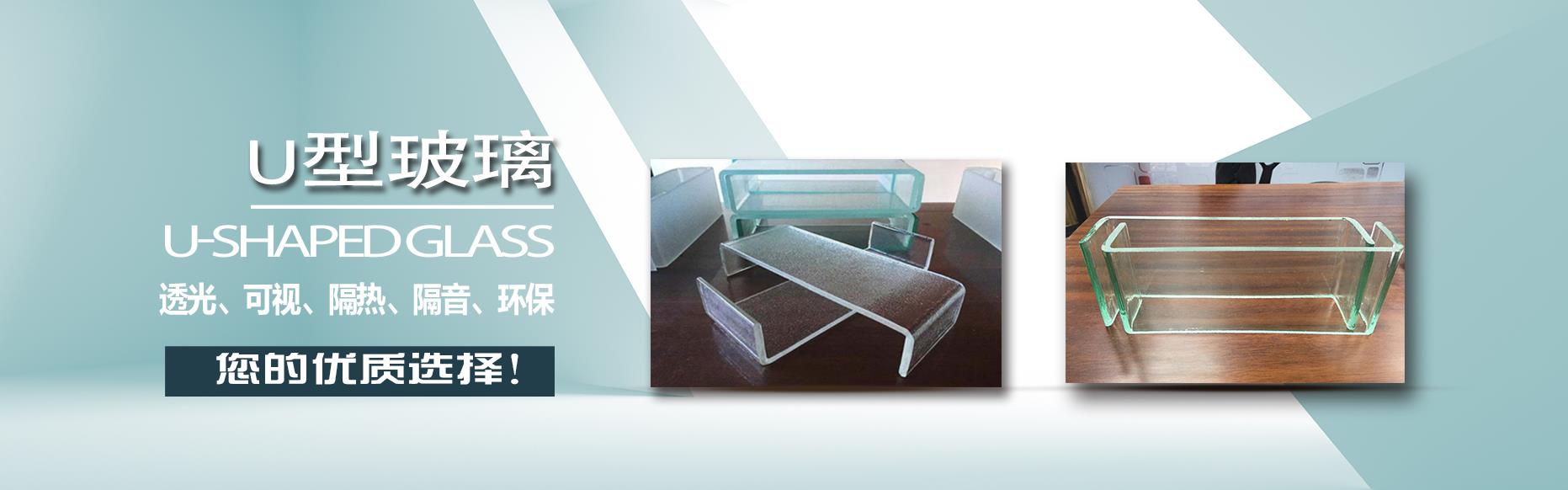

- Analysis of U-shaped glass in the market

- Signing the U-shaped glass project of Nanjing General shan Junior High School

- Performance and application of curved tempered glass

- Cause Analysis and Control of Stress Spot on Tempered Glass

- Hangzhou Xiangjie tells you how to install U-shaped glass

- Energy-saving and environmental-friendly building curtain wall glass will become the new darling of the future market

- How refractory materials are used in U-shaped glass furnace

- What are the characteristics of wire U-shaped glass

- Toughened glass manufacturers share their little knowledge of laminated glass

- Installation steps of building curtain wall glass

- Normal maintenance method of U-shaped glass curtain wall

- Where are the main characteristics of wire U-shaped glass

- U-shaped glass manufacturers take everyone to understand its design

- Do you understand the steps for installing frosted glass?

- Beijing Jinyu Intelligent Manufacturing Factory Ultra White Glass U-shaped Glass Project