1. Brick materials must be clearly marked. For example, stamp the product inspection qualification stamp and mark on the working surface, and type stack, type packaging, and bricks should be packed separately according to positive and negative tolerances. Fused cast refractory bricks should also indicate the unit weight, nominal size, production date and assembly number of the bricks. The pre-assembled bricks must also provide assembly drawings and photos.

2. Glass kiln refractory enterprises must notify the users of the departure date, vehicle number, delivery variety and quantity, and contract number in time when they are shipped, and submit product certification and test reports. When the unshaped refractory material leaves the factory, it must be accompanied by a construction manual indicating the construction related matters. The glass company should add the shipment notice to the refractory company in time.

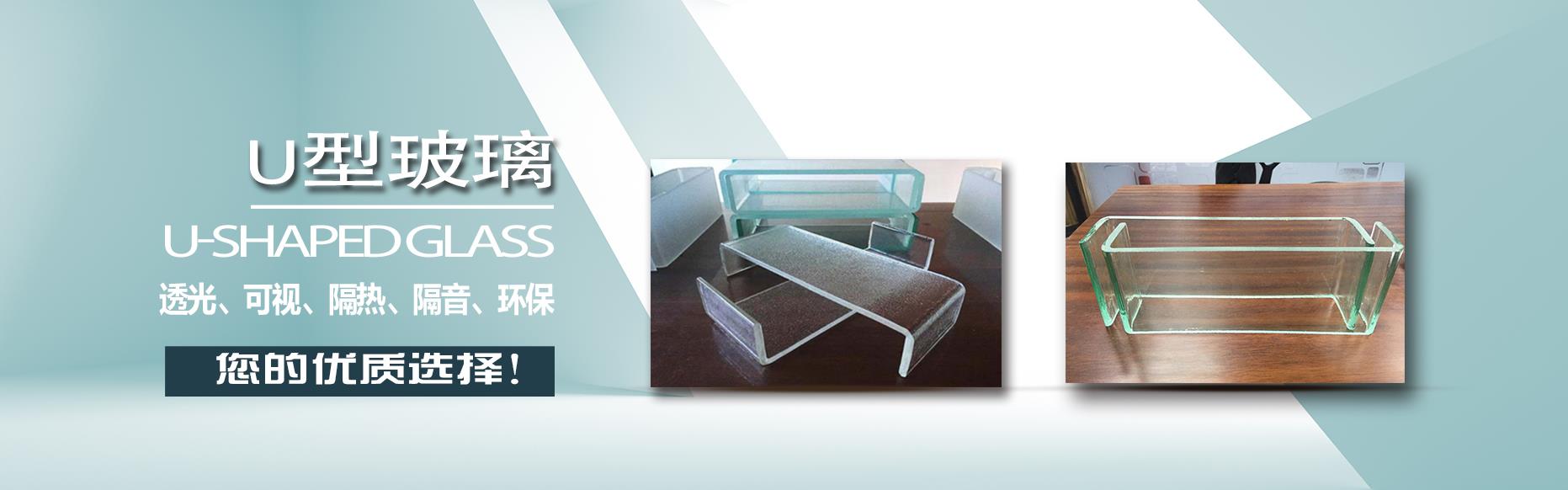

3.U-shaped glassThe packaging of refractory materials for kiln should be in accordance with the contract requirements and implement the relevant standards. There should be protective measures for vulnerable parts such as edges and corners. There should be shock-absorbing materials between the two bricks in the same packaging box, and the outer surface of the packaging box should be painted or written with the brick product name, model, quantity, supplier, user name, and marks such as rainproof, fragile, transportation, and code placement. The packaging of exported products must comply with the regulations of the Commodity Inspection Bureau on export packaging.

4. The refractory materials for glass kilns should be deposited in the warehouse immediately after they arrive at the glass enterprise. Open storage is prohibited. Different types and standards of refractory data (including indefinite refractory data) must be stacked in accordance with the corresponding requirements, and have a distinctive symbol, indicating the type, standard, quantity and storage date of the data. Generally, the principle of first-in first-out should be followed. The warehouse shall be set up with special personnel to keep it, and there shall be specific records for entering and leaving the warehouse.

5. The glass enterprise shall set up a special storage warehouse for refractory materials. The warehouse should meet the storage of refractory materials during the construction and cold repair of the furnace (including tin bath). Concrete should be used on the floor of the warehouse to ensure no water leakage, rain and snow leakage, good ventilation, and avoid high temperature and humidity. Refractory enterprises should also set up special warehouses, and it is strictly forbidden to store refractory in the open air before leaving the factory.

6. For time-sensitive refractory materials (such as alkaline materials and casting materials, etc.), the storage time should not be too long, and the specific time shall be implemented according to the standards of the corresponding products. If it has been damp during storage, take dehumidification measures in time, and sample to check the actual quality, and then decide whether to use it. If it can still be used, it is necessary to prolong the low-temperature baking time appropriately during use. Do not use materials that have been dampened or deteriorated.

Related News

- Analysis of U-shaped glass in the market

- Signing the U-shaped glass project of Nanjing General shan Junior High School

- Performance and application of curved tempered glass

- Cause Analysis and Control of Stress Spot on Tempered Glass

- Hangzhou Xiangjie tells you how to install U-shaped glass

- Stained glass is gradually expanding in the construction market

- Energy-saving and environmental-friendly building curtain wall glass will become the new darling of the future market

- What are the characteristics of wire U-shaped glass

- Toughened glass manufacturers share their little knowledge of laminated glass

- Installation steps of building curtain wall glass

- Normal maintenance method of U-shaped glass curtain wall

- Where are the main characteristics of wire U-shaped glass

- U-shaped glass manufacturers take everyone to understand its design

- Do you understand the steps for installing frosted glass?

- Beijing Jinyu Intelligent Manufacturing Factory Ultra White Glass U-shaped Glass Project

- An article lets you know what the use of stained glass is

- What can the processing of shaped glass be used for?