Sandblasting is a kind of work that uses tight air as the power to push the abrasive to the exterior of the workpiece to stop disposal, so it is called sand blasting, which is what we often say is the blast ingress ment, blast sprayer reinforcement disposal. Since sand was the only abrasive that could be used in the early stages of the blast ingresss, the blasting clearing was constantly known as sand blasting at that time and for a considerable period of time.

In fact, the blasting (spray) phenomenon is common in nature, sand, gravel and dust in the moment of constant impact on the mountains, it slowly abrasive, but this process is quite slow, not easy to be detected.

In a variety of appearance pre-disposal methods, blasting (spray clearance) effect than thorough, highly adaptable, widespread application, this is due to the liquidation of steel appearance fast, thorough;

Sand blasting enables the liquidated exterior to achieve both the desired cleanliness and the roughness of the exterior, and the adhesion of the progressive coating on the underlying exterior has two effects. No good paint can not be good for a long time attached to the exterior of the workpiece that has not been disposed of on the appearance. The function of pre-disposal of the exterior is to liquidate the appearance and generate on the outside to "lock" the roughness required for the coating. After the blasting workpiece exterior is coated with well-performing blastglass, the coating life can be more than 3.5 times higher than the same quality coating on the exterior after disposal by other methods. Another advantage of blasting (blast ingress liquidation) is that the appearance roughness can be confirmed in advance according to the request and is easy to complete during the liquidation process.

Related News

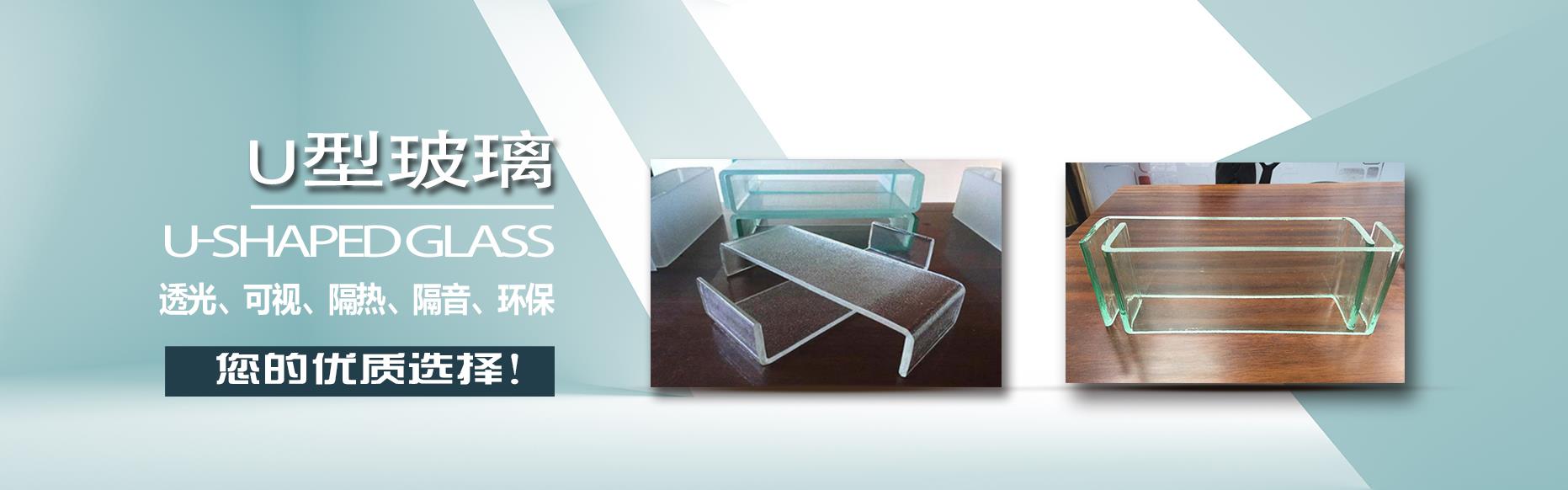

- Analysis of U-shaped glass in the market

- Signing the U-shaped glass project of Nanjing General shan Junior High School

- Performance and application of curved tempered glass

- Cause Analysis and Control of Stress Spot on Tempered Glass

- Hangzhou Xiangjie tells you how to install U-shaped glass

- Stained glass is gradually expanding in the construction market

- Energy-saving and environmental-friendly building curtain wall glass will become the new darling of the future market

- How refractory materials are used in U-shaped glass furnace

- What are the characteristics of wire U-shaped glass

- Toughened glass manufacturers share their little knowledge of laminated glass

- Product advantages of frosted glass installation

- U-shaped glass manufacturers introduce you

- Teach you the distinction and application of U-shaped glass

- Product performance of tempered glass

- Advantages of frosted glass in office cubicles

- What is stained glass?

- Can tempered glass be used in construction

- Methods for designing u-shaped glass

- U-glass product advantages you know?

- Product advantages of wire U-shaped glass