HangzhouTempered glassAs one of the safety glass, it is widely used in various doors and windows. The tempered glass with poor flatness will form the reflected optical deformation of the glass on the one hand after installation, affecting the appearance quality of the doors, windows and curtain walls, and on the other hand will also cause optical distortion of the glass, further affecting the visual effect of the doors, windows and curtain walls. In addition, the tempered glass with poor flatness will also affect the installation, so it is important to control the flatness of the tempered glass in the range of doors, windows and curtain walls.

Second, the details of the tempered glass control methods:

1, Hangzhou tempered glass's countermeasures against the deformation of the heating roller table Before the glass is tempered, allow the roller table to have sufficient time to preheat, so that the roller table is heated evenly, eliminate stress, and reduce the stress deformation of the roller. For the wear of the roller table, it is necessary to polish the entire roller when cleaning the roller, try to prevent the localization of the roller, and make the roller wear evenly and maintain the consistency of the roller. And often check and adjust the height of the roller table, so that the surface of the roller table during operation is a flat surface to maintain the flatness of the glass surface. The structure of the roller grille is to wind nylon rope on the surface of the metal roller as a heat insulation material. The glass cracks in the wind grille and simply cuts the nylon rope to form an uneven surface of the roller. It should be repaired in time and the nylon rope should be replaced.

2, Hangzhou tempered glass control measures against thermal deformation caused by uneven heating temperature

(1) There is a temperature difference between the upper and lower surfaces. When the glass twists upward, it means that the surface temperature on the glass is high. The upper surface temperature should be lowered, and at the same time, in order to maintain the heating temperature of the whole glass unchanged, the lower surface temperature should be appropriately increased; when the glass twists and turns downward, it means that the lower external surface temperature is higher than the upper external surface temperature, and the lower external surface temperature needs to be properly lowered while improving Upper surface temperature. If the tempering yield and tempering quality are affected when adjusting the temperature, the heating time should be properly extended or the heating time should be reduced.

(2) Hangzhou tempered glass is aimed at the deformation of the glass due to the temperature difference between the center and the edge. If the glass has a saddle shape, it means that the furnace body is not well insulated or the temperature setting value is marginally low. Temperature setting value; when the shape of the bottom of the glass appears, if it is due to the history of heat, it is necessary to temporarily not stack the glass, work in the furnace first, so that the temperature distribution in the furnace is uniform, and then put on the film; , The temperature setting parameters need to be adjusted to make the temperature distribution in the furnace even.

(3) Hangzhou tempered glass needs to overhaul the equipment in time to prevent the equipment from being in bad condition. It is necessary to clean the glass slag near the temperature sensor so that the temperature touched by the temperature sensor is the accurate furnace temperature. At the same time, it is to prevent multiple furnaces from being stacked in the same state.

3 Control measures against thermal deformation caused by uneven cooling Regarding the uneven stress occurring during cooling, the cooling rate of the glass surface can be adjusted by adjusting the wind pressure of the wind grille. If the glass is tortuous, this can be adjusted by increasing the wind pressure at the bottom of the air grid to increase the cooling rate of the outer surface of the glass; if the glass is tortuous, it needs to be adjusted by adding the wind pressure on the upper part of the air grid to increase the cooling rate of the outer surface of the glass .

The above is the relevant content brought to us by Hangzhou Tempered Glass, I hope to help us.

Related News

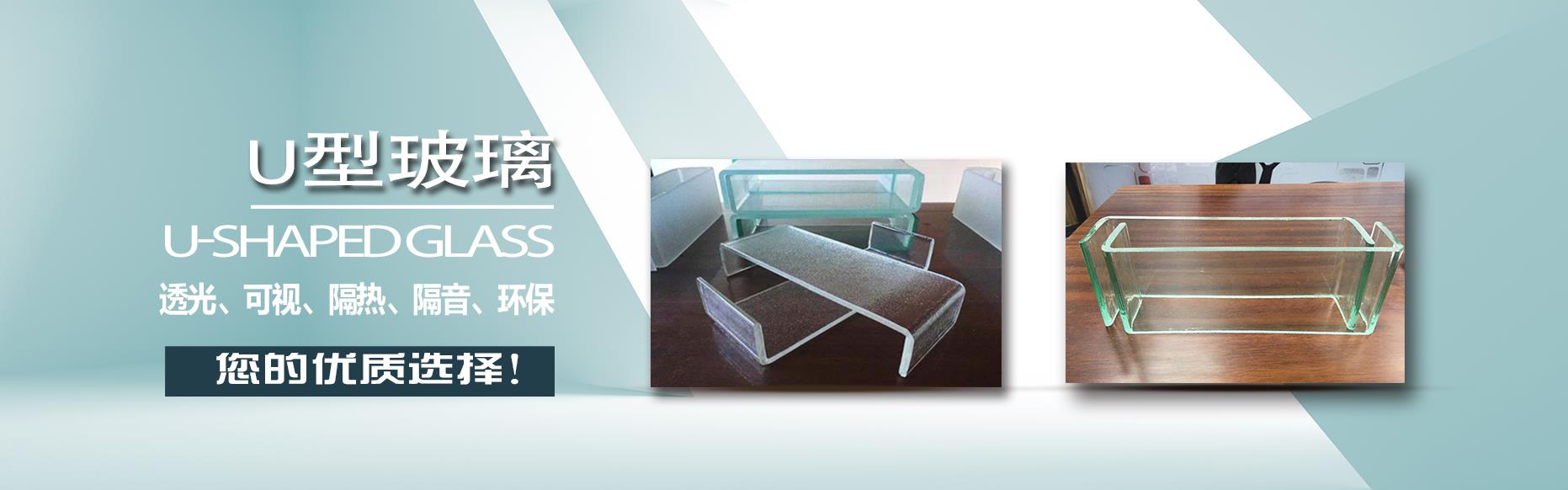

- Analysis of U-shaped glass in the market

- Signing the U-shaped glass project of Nanjing General shan Junior High School

- Performance and application of curved tempered glass

- Cause Analysis and Control of Stress Spot on Tempered Glass

- Hangzhou Xiangjie tells you how to install U-shaped glass

- Stained glass is gradually expanding in the construction market

- Energy-saving and environmental-friendly building curtain wall glass will become the new darling of the future market

- How refractory materials are used in U-shaped glass furnace

- What are the characteristics of wire U-shaped glass

- Toughened glass manufacturers share their little knowledge of laminated glass

- What causes the impact of tempered glass is not close

- Teach us how to distinguish between ordinary glass and tempered glass

- What is the development status of tempered glass so far

- Briefly describe the main types of sandblasted glass

- How many types of U-shaped glass are there

- The chemical tempering method of tempered glass

- What causes the tempered glass to explode?

- Why the toughened glass will not be clean

- Knowledge of the service life of popular tempered glass for everyone

- Application place of U-shaped glass curtain wall