0010010 nbsp; 0010010 nbsp; The toughened glass is not cleaned because the quality of the glass does not meet the standards. After tempering, glass bars, pits and other defects appear.

Whether the quality of tempered glass can meet the standard, in addition to the reason of the glass raw material, whether the setting of the process parameters is reasonable is the factor of the decision. Only by fully understanding their role and the relationship between them can high-quality tempered glass be produced. All parameters are designed around "uniform heating and agile cooling", but they are not isolated, they are an organic whole. It is necessary to consider them comprehensively to get a perfect process. Temperature-related glass shortcomings and corrective methods:

1, wave tendons

If the set temperature is too high and the heating time is too long, the glass will show waves. This is because the heating of the glass has now exceeded the critical point, and the glass has begun to soften. If this shortcoming occurs, as long as the heating time is shortened Can be solved.

2, pitting

If the heating time is too long, there will be pitting on the lower surface of the glass. The pitting can be divided into two types. One is densely distributed and has an orange peel shape. This is caused by too long heating time (especially {{0 }} Thick glass above mm, some units set the heating time very long in order to make it not broken,) can be adjusted according to the situation. The other is the individual star-shaped pits, which is formed because the appearance of the loading table and the ceramic roller is not clean, or the glass fragments of the wind grid roller table are not cleaned.

3, Baiwu

White mist is a white mark in the center of the surface under the glass. It usually appears in the first few furnaces of the initial production. This is because the surface temperature of the ceramic roller is too high. When the glass enters the furnace within the first tens of seconds , The outer surface of the glass is directly subjected to heat conduction and curled at the four corners. The contact surface between the glass and the ceramic roller becomes smaller, and the friction force with the ceramic roller increases, which will disappear with the decrease of the surface temperature of the ceramic roller. We can set the lower temperature lower and the lower power lower during the initial production. In addition, we must continue the production, and do not allow the furnace to work empty. If the production is not produced temporarily, we can turn off the heating switch to prevent White mist appears.

Related News

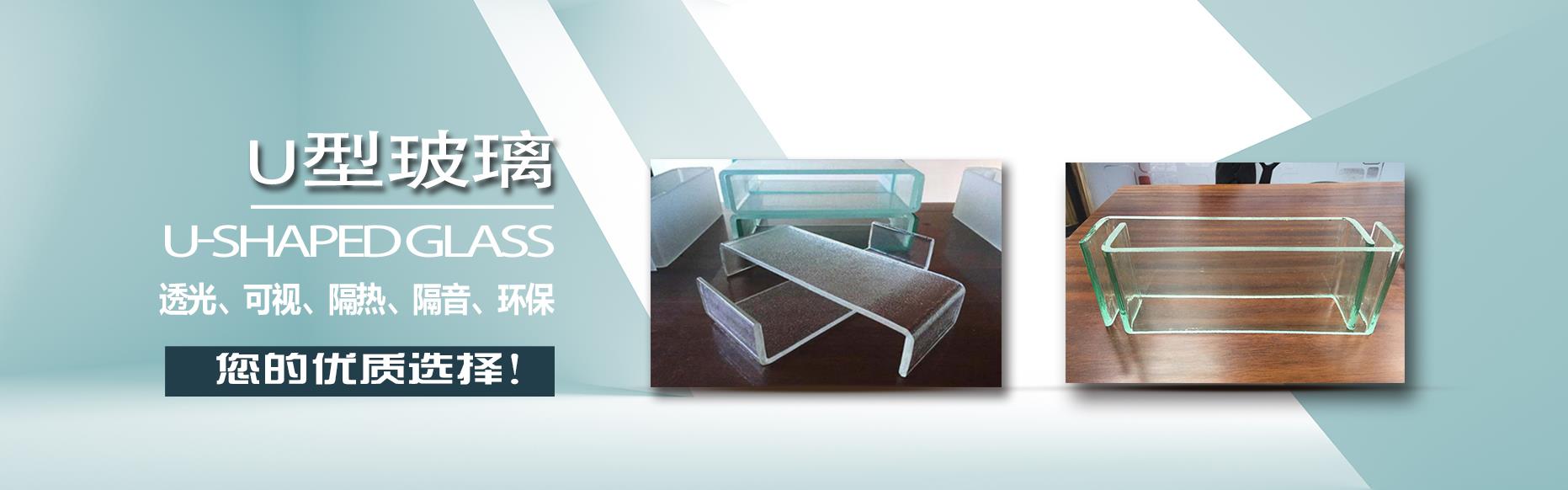

- Analysis of U-shaped glass in the market

- Signing the U-shaped glass project of Nanjing General shan Junior High School

- Performance and application of curved tempered glass

- Cause Analysis and Control of Stress Spot on Tempered Glass

- Hangzhou Xiangjie tells you how to install U-shaped glass

- Stained glass is gradually expanding in the construction market

- Energy-saving and environmental-friendly building curtain wall glass will become the new darling of the future market

- How refractory materials are used in U-shaped glass furnace

- What are the characteristics of wire U-shaped glass

- Toughened glass manufacturers share their little knowledge of laminated glass

- Knowledge of the service life of popular tempered glass for everyone

- Application place of U-shaped glass curtain wall

- Tempered glass manufacturers talk about the advantages of office spacing

- Benefits of using architectural glass

- Do you understand the difference between stained glass and lacquered glass?

- Blasting process for blasting glass

- Product advantages of frosted glass installation

- U-shaped glass manufacturers introduce you

- Teach you the distinction and application of U-shaped glass

- Product performance of tempered glass