The chemical tempering method is to modify the external composition of the glass and increase the external lamination stress to increase the mechanical strength and thermal stability of the glass. Because it strengthens the glass through ion communication, it is also called ion communication enhancement method. According to the type of communication ions and the temperature of the ion communication, it can be divided into an ion communication method below the change point (referred to as the low temperature method) and an ion communication method above the change point temperature (referred to as the high temperature method). The principle of the chemical enhancement method is to change the outer composition of the glass according to the mechanism of ion dispersion, and immerse the glass in a high-temperature molten salt at a certain temperature. Communicate with each other, the phenomenon of "congestion" occurs, so that the outer surface of the glass shrinks, and then increase the strength of the glass. "

According to the theory of the network structure of glass, the glassy substance is composed of a disordered three-dimensional network composed of oxygen-containing ionic polyhedrons, which are occupied by sAl or P ions. These ions form a network together with oxygen ions, and the network is filled with alkali metal ions (; nNa, K) and alkaline earth metal ions. During this period, the alkali metal ions are more active and can be easily removed from the glass. The chemical tempering method is based on the natural dispersion of ions and the dispersion of each other to modify the composition of the outer surface layer of the glass and then form the outer compressive stress layer. However, the external compressive stress layer produced by the ion exchange method is relatively thin, and it is very sensitive to micro defects in the external surface. A small external scratch is enough to reduce the strength of the glass.

Advantages and Disadvantages: The chemically strengthened glass is close in strength to the physically strengthened glass. It has good thermal stability, low processing temperature, and the product is not easily deformed. The product is not limited by thickness and geometry. The equipment is simple and the product is simple to complete. However, compared with physical tempered glass, chemical tempered glass has a long production cycle (up to tens of hours of exchange time), low efficiency and high production cost (molten salt cannot be recycled, and high purity requirements), and the fragments are similar to ordinary glass, safe Poor performance, and its function is unstable (poor chemical stability), physical functions such as mechanical strength and impact strength are prone to decline (also known as slack), and the strength declines quickly at any time.

Scope of application: ChemistryTempered glassIt is widely used in flat glass with different thickness, thin-walled glass and special-shaped glass products for bottles and cans, as well as fire-resistant glass.

Related News

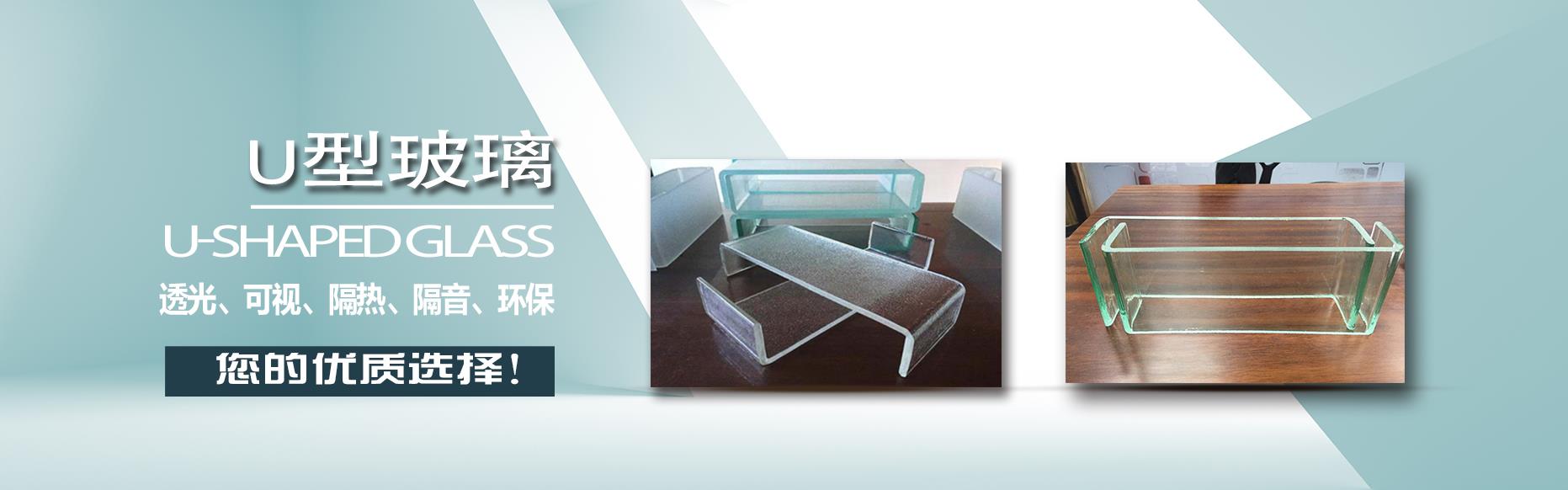

- Analysis of U-shaped glass in the market

- Signing the U-shaped glass project of Nanjing General shan Junior High School

- Performance and application of curved tempered glass

- Cause Analysis and Control of Stress Spot on Tempered Glass

- Hangzhou Xiangjie tells you how to install U-shaped glass

- Stained glass is gradually expanding in the construction market

- Energy-saving and environmental-friendly building curtain wall glass will become the new darling of the future market

- How refractory materials are used in U-shaped glass furnace

- What are the characteristics of wire U-shaped glass

- Toughened glass manufacturers share their little knowledge of laminated glass

- What causes the tempered glass to explode?

- Why the toughened glass will not be clean

- Knowledge of the service life of popular tempered glass for everyone

- Application place of U-shaped glass curtain wall

- Tempered glass manufacturers talk about the advantages of office spacing

- Benefits of using architectural glass

- Do you understand the difference between stained glass and lacquered glass?

- Blasting process for blasting glass

- Product advantages of frosted glass installation

- U-shaped glass manufacturers introduce you