Stained glassThe inorganic glaze (also known as ink) is printed on the surface of the glass, and then dried, tempered or thermally processed to sinter the glaze on the surface of the glass for a long time to obtain a decorative glass that is wear-resistant, acid and alkali resistant product. This product has high functionality and decoration. It has many different colors and markings, such as strips, meshes and electric drawings. It can also be designed separately according to different needs of customers.

Colored glazed glass generally refers to high-temperature glazed glass. After printing, the glaze needs to be sintered at the temperature of 600-700 ℃ on the glass surface. The low-temperature glaze is also called low-temperature ink, which is a product after printing the low-temperature ink on the surface of the glass and drying it.

Because low-temperature glaze does not need to pass high temperature, some organic pigments can be used in the pigment, so the color is richer and more selective. However, the adhesion of low-temperature glaze to glass is worse than that of high-temperature glaze, and most of them can be removed with nails, and the color durability does not allow high-temperature glaze. Generally used in home appliances and electronic glass. Screen printing refers to the method of printing glaze onto glass. Both high-temperature glaze and low-temperature glaze can be screen printed. Screen printing is generally relative to roll printing, roll printing is generally only full plate printing or regular drawings.

Oily glaze, water-based glaze, lead-free glaze

In the past, the glazes used for colored glazed glass are all oily glazes, that is, the pigments need to be distributed with oily solvents and alkyd resins for printing. Therefore, VOC (volatile organic compound) is produced in the production of colored glazed glass, which has a certain impact on the operator and the environment.

In recent years, water-based glazes have started to rise. Water-based glazes have replaced oily solvents and alkyd resins with water, making the production process of colored glaze glass healthier and more environmentally friendly. However, because the dispersibility and adhesiveness of water as a solvent is significantly worse than that of oil, the production process has higher requirements.

The appearance of lead-free glaze is also a requirement for health and environmental protection. In the early years, many glazes often participated in lead glass or other lead-containing materials in the glaze in order to reduce the melting point of the glaze and improve the color saturation. In recent years, following the concept of environmental protection, many glaze manufacturers have introduced lead-free glazes, whose functions are basically similar to those of leaded glazes.

Glazed drawings and visual illusions

Colored glazed glass for construction is usually used for designing a few pictures such as dots and lines. The good design of these pictures can make the construction and space show a simple and elegant style. However, in some cases, visual illusion will occur when a few pictures are handled carelessly.

Performance characteristics of stained glass:

1. It is cheaper and easier to install than other materials such as brick, stone or wood.

2. Various colors and pictures (generally can be customized according to customer requirements), with a wide selection. In the curtain wall combination, it can reflect other glasses or carry out color matching.

3. Stained glass can be installed on the support structure.

4. It has the characteristics of non-absorption, no penetration and easy to clean.

5. The color glaze is an inorganic color glaze of the same glass material, which does not fade or peel off, so the original color tone is consistent with the building life.

6. Colored glaze is easy to accept the non-rigid viscose used to block the arch shoulder.

7. The glazed surface can absorb and reflect part of the solar heat energy, which has the effect of saving energy.

8. It can be used for composite processing such as coating, interlayer, and synthetic hollow to obtain special functions for other uses.

9. After tempering, the product has good mechanical function, anti-shock function and thermal shock resistance function, and higher safety function.

10. The shading effect is remarkable.

0010010 nbsp;

Related Industry Knowledge

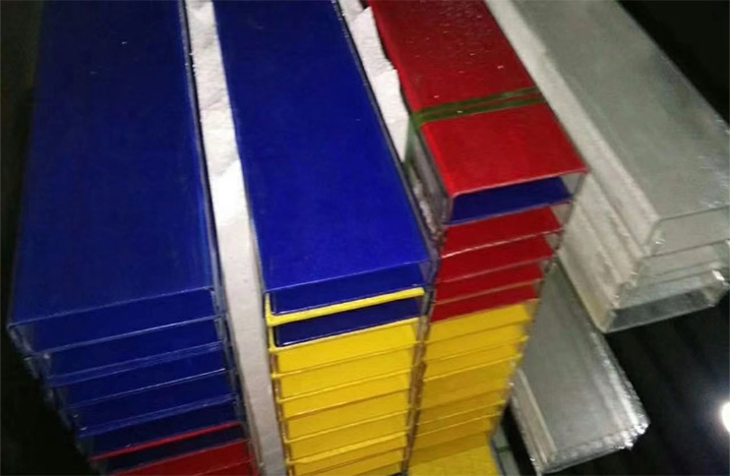

- What are the main features of U-shaped glass as a new wall material?

- The development of energy-saving and environmental protection characteristics of architectural curtain wall glass in the market

- Will you design U-shaped glass

- Related concepts about wire U-shaped glass

- Analysis of the factors causing stress spots in the tempered glass

- Technological factors of producing stress spot on tempered glass

- Detailed explanation of physical properties of U-shaped glass

- What kind of problems will occur with the chemical composition of tempered glass

- Tips for selecting frosted glass

- U-shaped glass manufacturers-hot bending glass characteristics and market

- Teach you how to distinguish between tempered glass and ordinary glass

- Analysis of maintenance tips for toughened glass

- Take everyone to understand what is sandblasted glass

- Improve the bearing capacity of tempered glass from many aspects

- The importance of building U-shaped glass curtain wall for shading

- Teach you how to better install u-shaped glass curtain wall

- U-shaped glass product performance comparison and advantages

- U-shaped glass construction organization plan

- Did you choose the right tempered glass

- How to install the frosted glass in the bathroom?