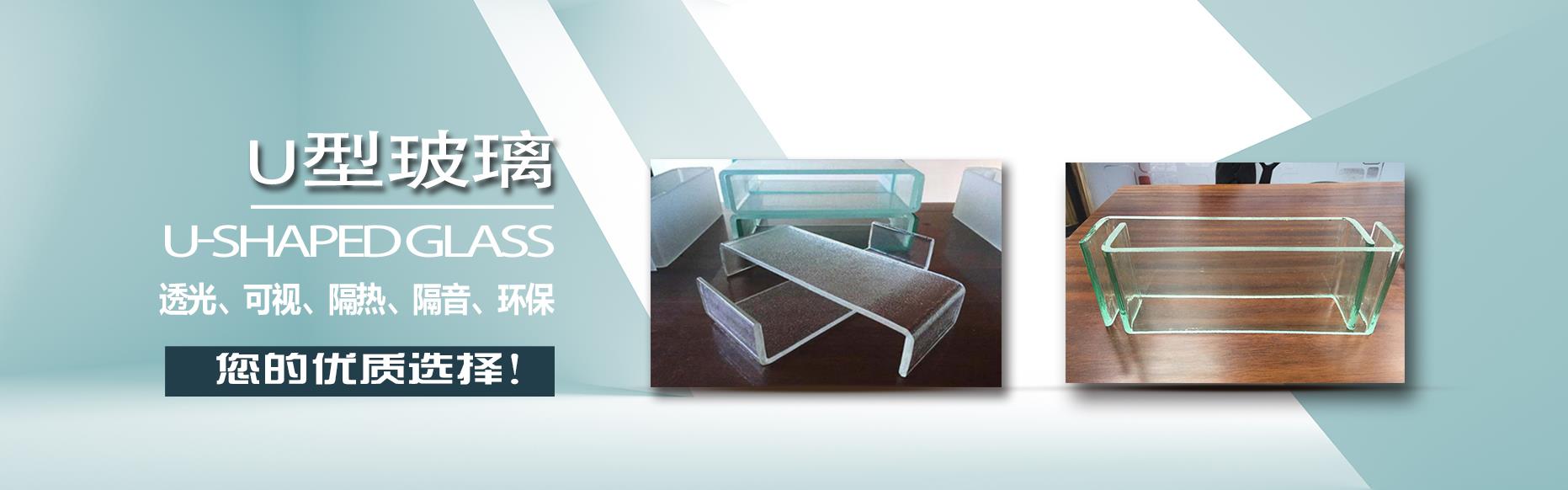

U-shaped glass is named because its cross-section is U-shaped. Its raw materials are used glass and quartz sand. The raw materials are melted at a temperature of about 1470 ℃, and are continuously produced by calendering. Another method of structural glass curtain wall is to add a pressure plate to the horizontal or vertical side of the fully hidden frame glass curtain wall to form a horizontal or vertical structural glass curtain wall. The following is the introduction of the main contents of the installation method of u-shaped glass curtain wall brought by Hangzhou Xiangjie Glass Co., Ltd. for reference.

U-shaped glass curtain wallInstallation method one

The glass is pasted on the glass frame with installation grooves on the two vertical sides, and the vertical side of the glass frame is fixed on the vertical rod of the aluminum alloy grid system with a fixing piece; In the mosaic slot. The bonding of the glass and the vertical edge of the glass frame is done by glue injection in a special workshop in the factory. The appearance of the data is clean and guaranteed, and the bonding quality is good. The glass frame is shipped to the site for installation only after the structural adhesive is completely cured, ensuring the bonding quality.

U-shaped glass curtain wall installation method two

The coated glass is first fixed in the inlaid grooves of the aluminum alloy profiles at the top and the bottom, forming a glue seam empty groove on the surface of the glass and the vertical rod, and then filling the glue seam empty groove with structural glue on the site to form a vertical structure plastic glass assembly system. This production method is caused by injection of glue on site, the appearance of the data is clean and dry, and the environmental cleanliness during injection is difficult to ensure sufficient guarantee. In addition, the structural adhesive often receives wind load before curing, which affects the bonding strength. It is generally limited to buildings with no installation gap between the building and the aluminum alloy structure system. Various methods should be used to temporarily close the glue injection site during the glue injection. The aluminum and glass bonding surfaces should be cleaned. Generally, the glue cannot be injected on the spot in strong windy days, rainy days and winter icing

Related Industry Knowledge

- What are the main features of U-shaped glass as a new wall material?

- The development of energy-saving and environmental protection characteristics of architectural curtain wall glass in the market

- Will you design U-shaped glass

- Related concepts about wire U-shaped glass

- Analysis of the factors causing stress spots in the tempered glass

- Technological factors of producing stress spot on tempered glass

- Detailed explanation of physical properties of U-shaped glass

- What kind of problems will occur with the chemical composition of tempered glass

- Tips for selecting frosted glass

- U-shaped glass manufacturers-hot bending glass characteristics and market

- U-shaped glass product performance comparison and advantages

- U-shaped glass construction organization plan

- Did you choose the right tempered glass

- How to install the frosted glass in the bathroom?

- What are the advantages of wire U-shaped glass in life

- Xiangjie shaped glass teaches you to identify fireproof glass

- What are the advantages of office frosted glass partition

- Analysis of the reasons why the weld scars of tempered glass cannot be removed

- Frosted glass VS frosted glass

- U-shaped glass curtain wall selection glass requirements