Technological factors of stress spots in toughened glass

1 Heating factor

The glass has uneven heating in the planar direction before quenching. After quenching and cooling of unevenly heated glass, the compressive stress will be smaller in the high temperature area, and the compressive stress will be greater in the low temperature area. Uneven heating will cause uneven compressive stress on the glass surface. The main factors leading to uneven heating are the difference in heater power. The temperature in the area with high heating power is high, and the temperature is low; the heater fails to heat normally; the temperature sensor fails or the calibration is not accurate; the temperature setting is not reasonable, the furnace The side of the body has more heat dissipation, the temperature setting should be slightly higher than the middle, the heat absorption in the middle of the glass is more than the side, and the temperature in the middle is slightly higher than the side. These factors are not reflected in the setting will cause heating The glass is unreasonably placed. Because the roller table is a poor conductor of heat, repeated use of an area will cause the temperature of the area to decrease and the area where the glass is not placed. The temperature of this area is relatively high. The temperature is relatively high; the heating furnace is poorly sealed, and there is more local heat dissipation, resulting in uneven temperature.

2. Cooling factors

The tempering process of glass is rapid cooling after heating, and the cooling process is as important as the heating process for the composition of the tempering stress.Tempered glassThe uneven cooling in the plane direction before the quenching is the same as the uneven heating, which can also cause uneven stress. Areas with large cooling strengths have large surface compressive stresses, and areas with small cooling strengths have small compressive stresses, and uneven cooling will cause uneven stresses to spread on the glass surface. The main factors leading to uneven cooling are the unreasonable distribution of the air nozzles of the fan, the uneven gap of the air nozzles, the uneven distribution of the wind pressure on the glass surface, and the uneven cooling of the glass surface. The heat conduction capacity of the channel is too large, and the part in contact with the roller table is rapidly cooled, and the part that is cooled first will form a large compressive stress. Uneven heating and cooling of the glass is the main reason for the occurrence of stress spots. It is only possible to find out the factors that affect the uneven heating and cooling in the design and manufacture of the tempering furnace, strengthen the process control, and strictly abide by the operating regulations. Reduce the generation of stress spots.

Related Industry Knowledge

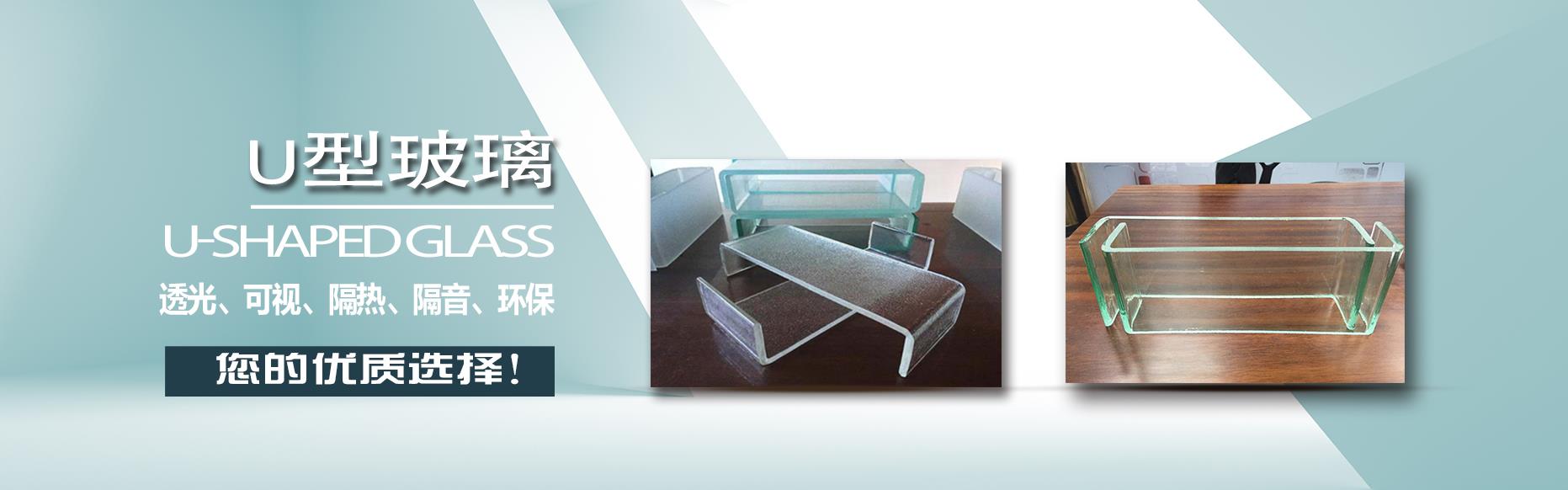

- What are the main features of U-shaped glass as a new wall material?

- The development of energy-saving and environmental protection characteristics of architectural curtain wall glass in the market

- Will you design U-shaped glass

- Related concepts about wire U-shaped glass

- Analysis of the factors causing stress spots in the tempered glass

- Detailed explanation of physical properties of U-shaped glass

- What kind of problems will occur with the chemical composition of tempered glass

- Tips for selecting frosted glass

- U-shaped glass manufacturers-hot bending glass characteristics and market

- Depth analysis of wire U-shaped glass

- What is the difference between stained glass and painted glass

- What is the development trend of frosted glass

- What are the ranges of tempered glass that must be used

- Decorative characteristics of stained glass in the city

- What you do n’t know about stained glass!