Any frosted glass can be calledFrosted glass. With the development and strength of the decoration industry, art glass relies on its good light-transmitting, visual, thermal insulation, sound insulation, environmental protection and other irreplaceable decoration effects, which increases the vitality of space decoration and is loved by people.

Frosted glass In recent years, frosted glass, as a hazy art glass, has added beauty to the space decoration. It can be described as a new darling of art glass and added wings to art glass. Frosted glass is almost everywhere in the decoration space, background walls, ceilings, dining tables, screens, entrances, partitions, floors, stairs, doors and windows, glass coffee tables ... are widely used in homes, hotels, bars, KTV, cafe On the decoration of the wild landscape. Frosted glass organically combines the interior and exterior landscape through artistic decoration, which greatly improves the level of space decoration.

Frosted glass is divided into chemical processing methods and physical processing methods from the processing technology, such as: acid corrosion frosted glass and sandblasted frosted glass.

Handprint-free glass is further processed on the basis of frosted glass, which makes the glass surface smoother and more delicate, and will not leave fingerprints and does not need to be scrubbed. Its production process.

Drafts-Screen Making-Printed Glass Etching Ink-Washout-Products

1. Draft: Design the required markings with a computer. The small format can be output by a laser printer, the large format can be engraved on a black sticky note by a computer engraving machine or output by a laser phototypesetting machine.

2. Screen-making plate: Please use 100-180 mesh polyester screen for screen printing. Try to choose monofilament polyester screen cloth. Make plate with water-sensitive photoresist.

3. For printing glass etching ink, it is necessary to remove the dirt, wetness, and sufficient frosting paste on the surface of the glass before printing. Avoid using iron, try to use "bamboo" products. When printing, you need to scrape the screen twice. The intention is to Add ink. For craft printing, you can scrape the etching ink from one end to the other end, and then lift the scraper behind the ink, and then scrape toward the end of the ink. The intention is to add ink. That is to say, it arrives on the surface of the glass Aspirational ink volume. If printing in winter, the etching ink should be heated to 20%-40. It is better to use float glass when using glass, flat glass is not desirable. Because the thickness of the glass is uneven, after the glass is hot pressed, the cooling is uneven and the material structure of the glass is uneven, so even after printing, the planar effect of the etching is uneven.

4. For scouring, leave the printed glass for three minutes and then place it in the pool for scouring or washing with tap water. After the water on the glass dries, a snow-like pattern appears. This kind of glass is very popular in the market and is loved by a wide range of customers. Using the above process, such as tea sets, handicrafts, social mirrors, glass containers, etc. can be made.

0010010 nbsp;

0010010 nbsp;

Related News

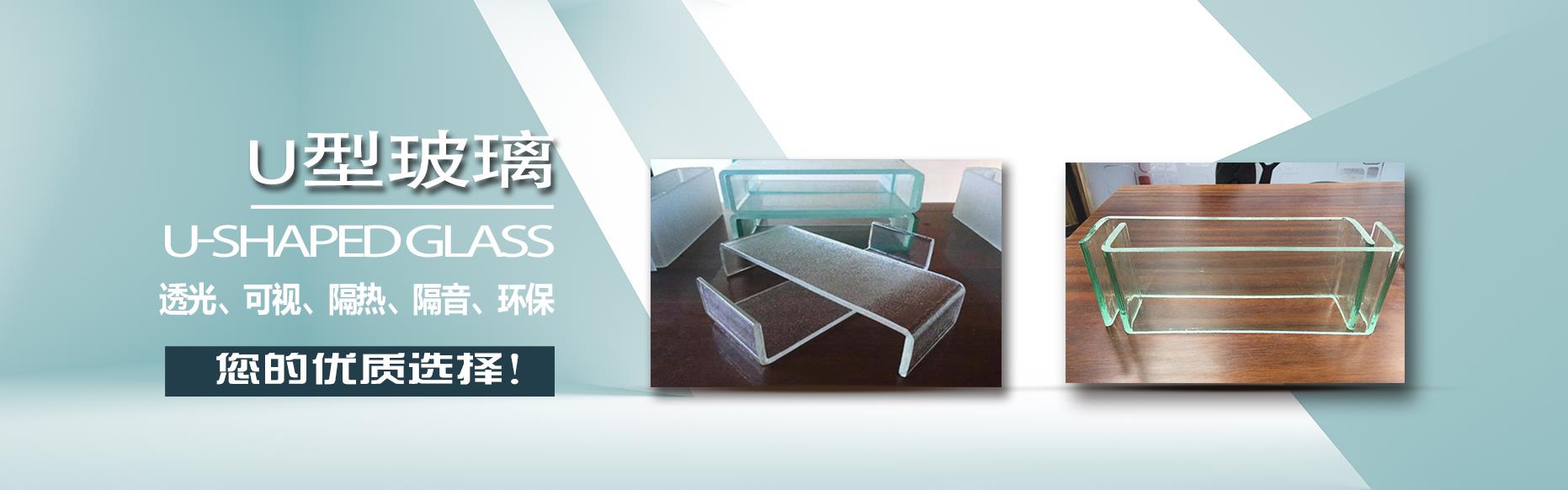

- Analysis of U-shaped glass in the market

- Signing the U-shaped glass project of Nanjing General shan Junior High School

- Performance and application of curved tempered glass

- Cause Analysis and Control of Stress Spot on Tempered Glass

- Hangzhou Xiangjie tells you how to install U-shaped glass

- Stained glass is gradually expanding in the construction market

- Energy-saving and environmental-friendly building curtain wall glass will become the new darling of the future market

- How refractory materials are used in U-shaped glass furnace

- What are the characteristics of wire U-shaped glass

- Toughened glass manufacturers share their little knowledge of laminated glass

- Wire U-shaped glass is enough to make you amazing

- Use of colored glazed glass to decorate urban colors

- From what aspects should the improvement of architectural glass start?

- How to improve the bearing capacity of tempered glass

- Characteristics and style of sandblasted glass

- Reasonable frosted glass installation partitions show grade

- Details of the types of tempered glass

- Low-E insulating glass and tempered glass which is better

- Where can the film-strengthened tempered glass be applied?

- What are the characteristics of tempered glass