Sand blasting is a kind of work that uses compressed air as a power to push the abrasive to the surface of the workpiece for processing. It is called sand blasting, which is what we often say shot blasting finishing and shot blasting strengthening treatment. Because sandblasting was the only abrasive that could be used in the early days of shot peening technology, shot peening was known as sandblasting at that time and for a long period of time later.

In fact, the phenomenon of sand blasting (shot peening) is widespread. In nature, sand, gravel, and dust continuously impact the mountain range at a moment, slowly abrading it. This process is very slow, and it is not easy for us to notice That's it.

Among various pretreatment methods of surface appearance, sandblasting (blasting finishing) has a more thorough function, stronger adaptability, and a wider range of use. This is because: finishing steel appearance is faster and more thorough; only sandblasting can be used. Formulate 4 sorts of sorts that we can all accept to identify; sandblasting can sort out the surfaces that are usually difficult to sort out, and use some special tools to sort out the inner and outer surfaces of the pipes, and the cost of sandblasting is lower.

Sandblasting can achieve the required cleanliness of the finished surface together and a certain roughness of the surface, and improve the adhesion of the coating on the basic surface. No matter how good the coating is, it will stick to the surface of the workpiece that has not been treated for a long time. The role of surface pretreatment is to sort out the surface and generate the required roughness on the surface to 0010010 quot; lock 0010010 quot; the coating. After the industrial coating with outstanding performance is applied on the surface of the blasted workpiece, the coating life can be more than 3. 5 times longer than the same quality coating on the surface after other methods. Another advantage of sandblasting (blasting finishing) is that the surface roughness can be confirmed in advance according to the requirements, and it is easily achieved during the finishing process.

Related News

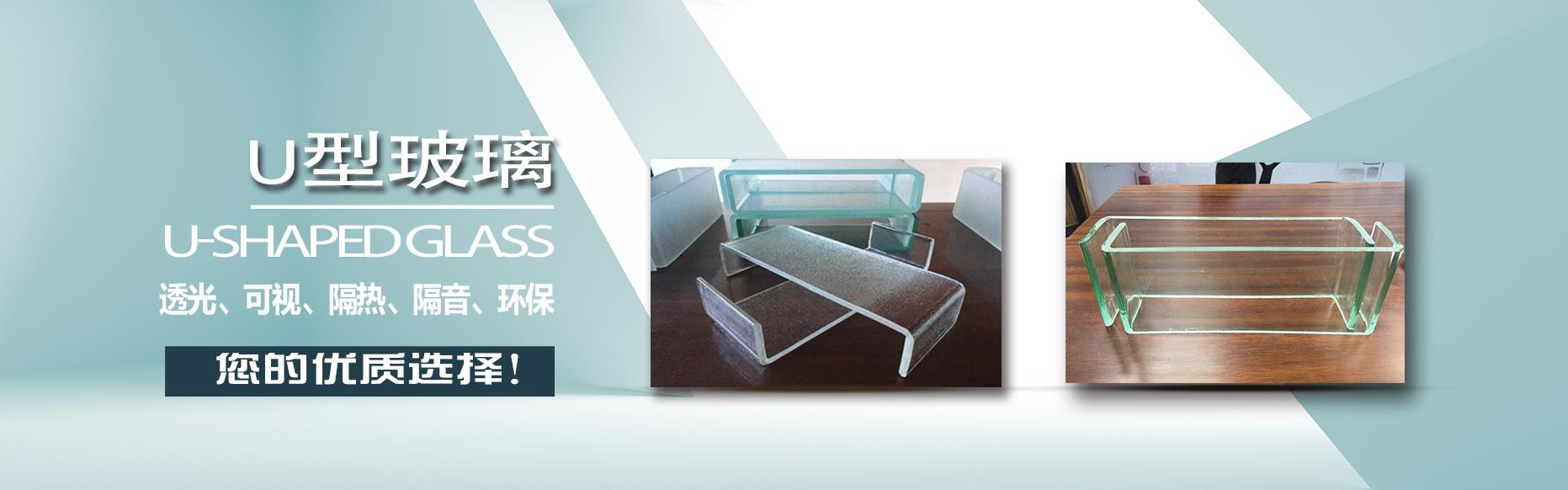

- Analysis of U-shaped glass in the market

- Signing the U-shaped glass project of Nanjing General shan Junior High School

- Performance and application of curved tempered glass

- Cause Analysis and Control of Stress Spot on Tempered Glass

- Hangzhou Xiangjie tells you how to install U-shaped glass

- Stained glass is gradually expanding in the construction market

- Energy-saving and environmental-friendly building curtain wall glass will become the new darling of the future market

- How refractory materials are used in U-shaped glass furnace

- What are the characteristics of wire U-shaped glass

- Toughened glass manufacturers share their little knowledge of laminated glass

- Analysis of the advantages of architectural curtain wall glass as decoration

- Why steeled glass needs to be used carefully