With the continuous development of glass materials, the variety of glass continues to increase. Sand-blasted glass is now a relatively new type and has been sought after by many customers. So, what exactly is sandblasted glass? What are the varieties and precautions of sandblasted glass? Let's take a look together!

Sand-blasted glass, as the name implies, is a process of spraying high-pressure diamond powder mixed with water on glass and grinding it. It has the characteristics of novel design, simple construction, energy saving, good processing effect and long service life. It is mostly used indoors. The partitions, screens, bathrooms, furniture, doors and windows are popular among customers.

There are many types of sandblasted glass, which can be divided into three types: full sandblasted glass, striped sandblasted glass, and computer-painted sandblasted glass. Let's take a closer look at these three types of sandblasted glass!

(1) Full-blasted glass: It is a type of sand-blasted glass, which is coated with a layer of emery in the glass. It is often used in the bathroom partitions to protect privacy.

(2) Striped sandblasted glass: As the name implies, it is a picture of stripes in sandblasted glass, which has the characteristics of flat, smooth and shiny appearance, and is very popular with the owners.

(3) Computer drawing sandblasted glass: it is a sandblasted glass picture made using computer technology, which is not only simple and convenient, but also very beautiful.

Matters needing attention

(1) Properly spaced: When installing sandblasted glass, we must place the spray gun and the glass at a proper distance, so as to avoid the glass from breaking due to excessive force of the spray gun.

(2) Moving speed is stable: use a spray gun to move on the glass, it must be stable, otherwise it may cause uneven sandblasting and affect the overall beauty.

(3) Check: Before sanding, we must first check whether the nozzle is blocked, and then check whether the emery pipe is blocked. If there are these problems, we must clean up in time to ensure uniform sand production.

(4) Investigate the texture: After sanding, we can investigate whether the carved texture is uniform from the back of the light. If the texture is not uniform, we will have to re-finish it.

(5) After cleaning all the sand: After all the processes have been completed, we will tear off the engraving paper first, and then clean the adjacent sand with water, but we must pay attention to it The remaining sand is left on the glass surface to avoid scratching the glass surface.

The above is a detailed introduction about what is sandblasted glass, the types of sandblasted glass and precautions. I believe everyone has a certain understanding of sandblasted glass, so you must pay more attention to it during construction to avoid destroying the beauty of the glass.

Related Industry Knowledge

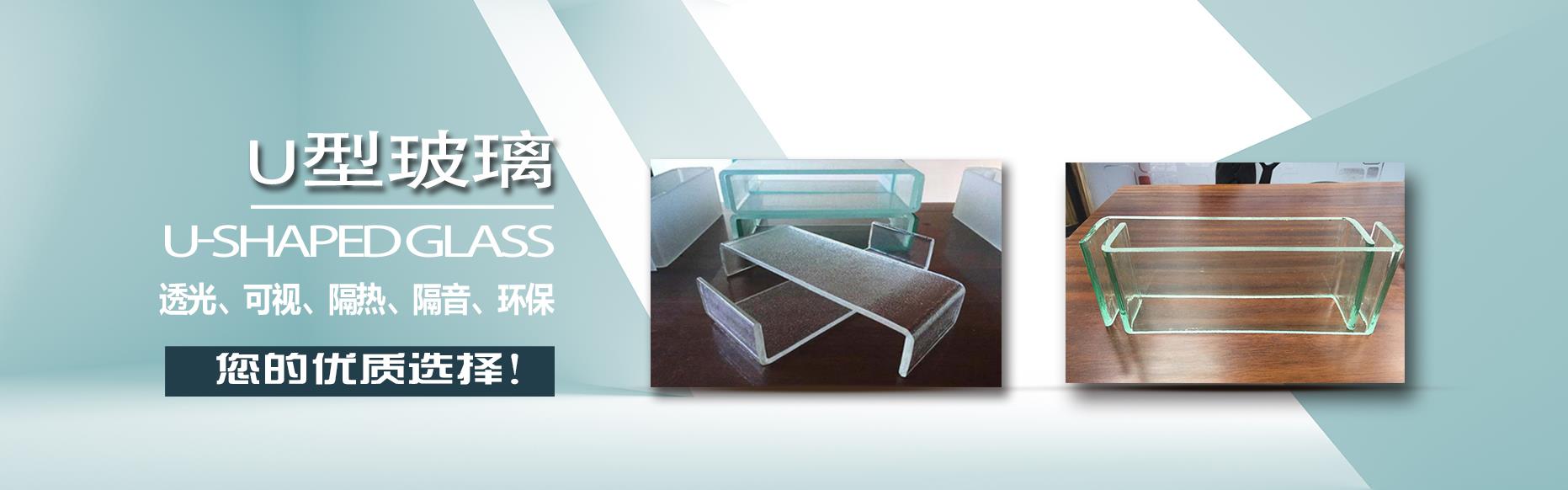

- What are the main features of U-shaped glass as a new wall material?

- The development of energy-saving and environmental protection characteristics of architectural curtain wall glass in the market

- Will you design U-shaped glass

- Related concepts about wire U-shaped glass

- Analysis of the factors causing stress spots in the tempered glass

- Technological factors of producing stress spot on tempered glass

- Detailed explanation of physical properties of U-shaped glass

- What kind of problems will occur with the chemical composition of tempered glass

- Tips for selecting frosted glass

- U-shaped glass manufacturers-hot bending glass characteristics and market

- Do you know the purpose of wire U-shaped glass?

- How to make tempered glass effectively reduce the problem of self-explosion

- What is the advantage of tempered glass compared with general glass

- Sharing tips for choosing shower room tempered glass

- There are several key points for analyzing the quality of tempered glass

- What are the common types of architectural glass in the light description

- What are the process requirements for installation of architectural curtain wall glass

- The advantages of using frosted glass after installation

- Do you know the technical characteristics of sandblasted glass

- Notes on the use of tempered glass