0010010 nbsp; 0010010 nbsp; In our daily life, all kinds of glass are always indispensable. Now, there are many kinds of glass, and many people must have heard of it. After blasting glass, the application of blasting glass is very extensive, and sandblasting glass will be used in many places. Because sandblasting glass uses sandblasting technology, it will give people a fuzzy beauty, which can be used as a screen, and Can be used as a partition. Today I will introduce some knowledge about sandblasted glass. Friends who do n’t know about sandblasted glass may wish to learn with him. I believe that sandblasted glass will make our home decoration more and more. beautiful.

Sandblasting is a kind of work that uses compressed air as the power to push the abrasive to the surface of the workpiece for processing. It is called sandblasting, that is, we often say shot peening and shot peening. Since sandblasting was the only abrasive that could be used in the early days of shot peening technology, shot peening was always known as sandblasting at that time and for a long period of time later. In fact, the phenomenon of sand blasting (shot peening) is widespread. In nature, sand, gravel and dust constantly impact the mountain range at a moment, slowly abrading it, but this process is moderately slow and not easy to be noticed Never mind.

Among the various surface pretreatment methods, the effect of sand blasting (shot peening) is thorough, adaptable, and has a wide range of applications. This is because the finishing of the steel surface is fast and thorough. As long as the sandblasting can be used to sort out the surfaces that are usually difficult to sort, the use of some special tools can sort the inner and outer surfaces of the pipeline, and the cost of sandblasting is low. Sandblasting can achieve the required cleanliness of the finished surface together and a certain roughness of the surface, and improve the adhesion of the coating on the basic surface. No matter how good the coating is, it will not adhere to the surface of the workpiece that has not been treated for a long time. The effect of surface pretreatment is to sort out the surface and generate the required roughness on the surface to 0010010 quot; lock 0010010 quot; the coating.

After the industrial coating with good performance on the surface of the blasted workpiece, the coating life can be more than 3. 5 times longer than the same quality coating on the surface after other methods. Another advantage of sandblasting (blasting finishing) is that the appearance roughness can be confirmed in advance according to the requirements, and it can be easily reached during the finishing process.

Related Industry Knowledge

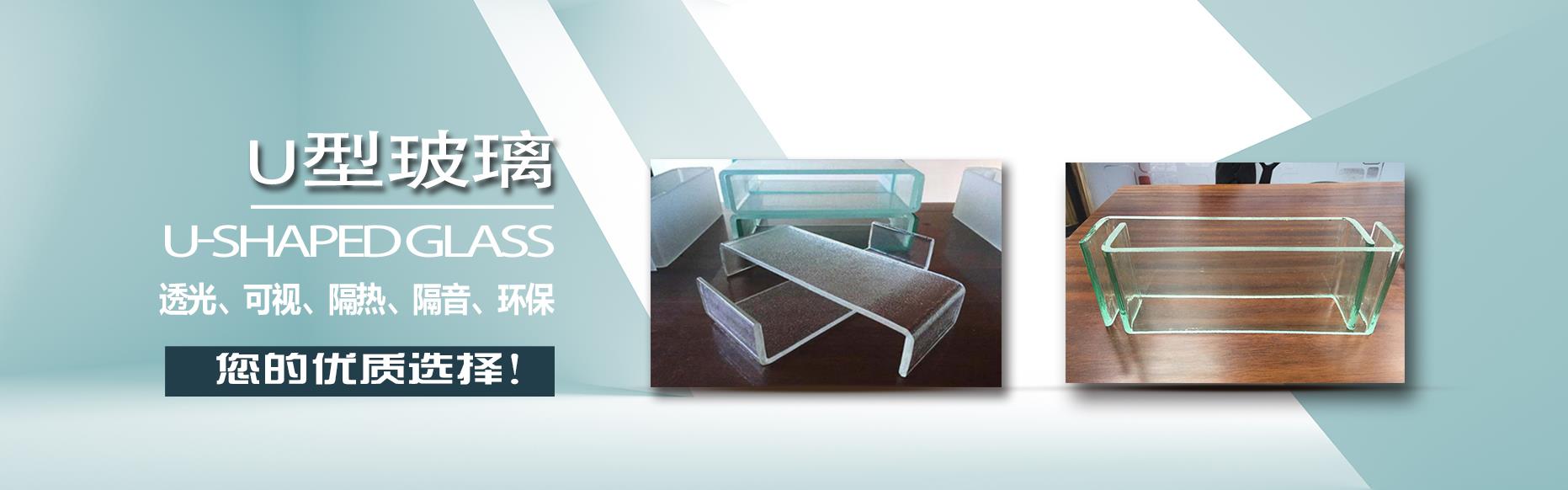

- What are the main features of U-shaped glass as a new wall material?

- The development of energy-saving and environmental protection characteristics of architectural curtain wall glass in the market

- Will you design U-shaped glass

- Related concepts about wire U-shaped glass

- Analysis of the factors causing stress spots in the tempered glass

- Technological factors of producing stress spot on tempered glass

- Detailed explanation of physical properties of U-shaped glass

- What kind of problems will occur with the chemical composition of tempered glass

- Tips for selecting frosted glass

- U-shaped glass manufacturers-hot bending glass characteristics and market

- Notes on the use of tempered glass

- How to find a good u-shaped glass manufacturer

- What are the repair methods for building curtain wall glass

- Tips for maintenance of dimming glass in architectural glass curtain wall

- Analysis of accidents caused by tempered glass in recent years

- Application and significance of special-shaped glass

- Sandblasting process in sandblasted glass

- Facade decoration commonly used in architectural curtain wall glass

- What equipment do you need for sandblasted glass?

- u-glass price installation process