Wire U-shaped glassAlso known as shatterproof glass and wire glass, wire glass has the advantages of fire resistance, security, and anti-theft.

Wire-cut glass is a special glass formed by pressing a wire mesh into a semi-liquid glass ribbon during the rolling production process. Compared with ordinary glass, wire glass has its different advantages. let's see it together:

0010010 nbsp; 0010010 nbsp; 0010010 nbsp; Wired glass is the general flat glass is heated to the red heat softening condition, and then the preheated iron wire or wire mesh is pressed into the glass Made in the middle. The characteristic of the wire-wound glass is superior in fire resistance, it can block the flame, it will not burst when burned at high temperature, and will not cause fragments to hurt people when broken. Other wire-cut glass also has anti-theft properties, glass breakage and barbed wire barrier. Wired glass is mainly used in curtain walls, partitions, glass sheds, doors and windows and other places.

Advantages: It is higher in strength than ordinary glass. When the glass is subjected to impact or temperature changes, it will break without breaking, without breaking, and avoid small pieces of angular pieces flying out and hurting people, such as fire spread, when the wire glass is heated and burst It can still maintain a fixed state and play a role in isolating the fire, so it is also called wire-cut fireproof glass.

Disadvantages: In the production process, the wire mesh is easily oxidized by high temperature radiation, and the surface of the glass may appear yellow and bubbles like "rust spots". Wire-cut glass is commonly used for curtain wall partitions, ceilings, and doors and windows that are susceptible to vibration.

Wired glass requires that the thermal expansion coefficient of the metal wire (mesh) is close to that of glass, and it is not easy to chemically react with glass. It has high mechanical strength and certain magnetic properties. The surface is clean and free of oil stains.

The thickness of the wire glass is generally above 5 MM. The varieties include embossed wire, polished wire and colored wire glass. There are flat wire, wave wire and groove wire, etc.

Wire-cut glass is a kind of anti-flash flat glass made by embedding metal wire or metal mesh in a glass plate. When impacted, it will only form radial cracks without splashing and hurting people. High-rise buildings and factories with strong shocks.

1. The wire mesh requires that the wire mesh and wire used in the wire glass are divided into ordinary steel wire and special steel wire. The diameter of the ordinary steel wire is 0. 4 mm or the diameter of the special steel wire is 0 . 3 mm or more. Wire mesh glass should be treated with spot welded wire mesh.

2, curvature.

3, size deviation length and width allowable deviation is ± 4. 0mm.

3. {{{1}} The wire-embossed glass should be within {{1}}. 0%.

3. 2 Wire polished glass should be within 0. 5%.

4, glass edge protrusions, notches, missing corners and skewed glass edge protrusions and notches must not exceed 6 mm in size, and skew dimensions must not exceed 4 mm Only one missing corner is allowed for a piece of glass, and the depth of the missing corner shall not exceed 6 mm.

Related Industry Knowledge

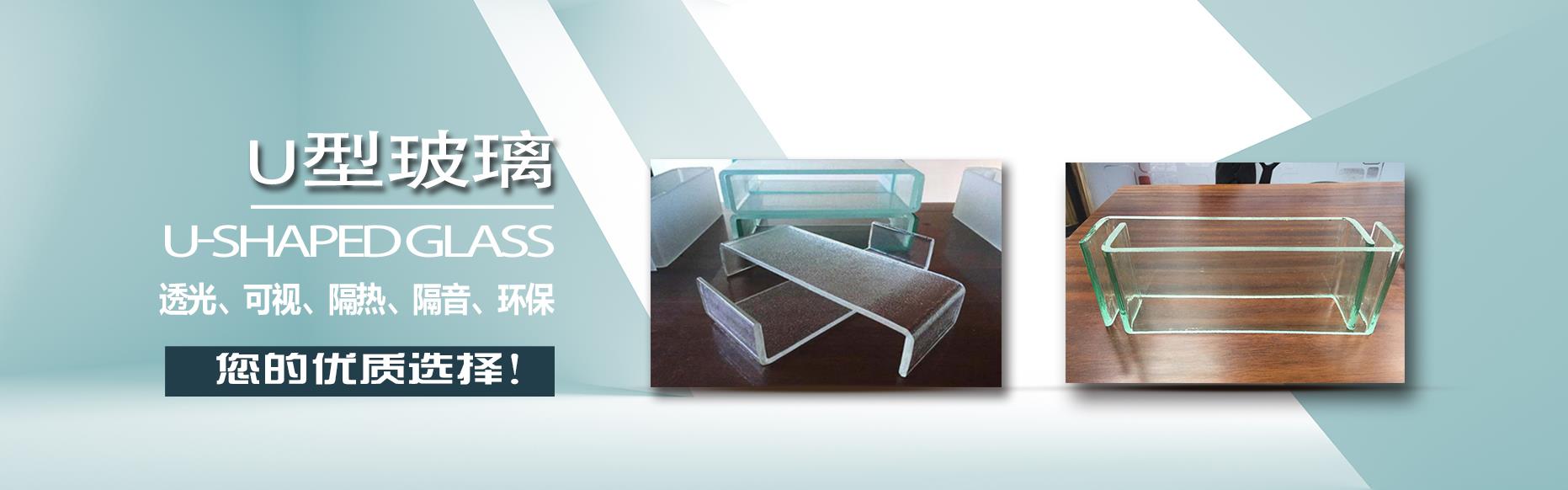

- What are the main features of U-shaped glass as a new wall material?

- The development of energy-saving and environmental protection characteristics of architectural curtain wall glass in the market

- Will you design U-shaped glass

- Related concepts about wire U-shaped glass

- Analysis of the factors causing stress spots in the tempered glass

- Technological factors of producing stress spot on tempered glass

- Detailed explanation of physical properties of U-shaped glass

- What kind of problems will occur with the chemical composition of tempered glass

- Tips for selecting frosted glass

- U-shaped glass manufacturers-hot bending glass characteristics and market

- What is the difference between stained glass and painted glass

- What is the development trend of frosted glass

- What are the ranges of tempered glass that must be used

- Decorative characteristics of stained glass in the city

- What you do n’t know about stained glass!

- Teach you how to distinguish between tempered glass and ordinary glass

- Analysis of maintenance tips for toughened glass

- Take everyone to understand what is sandblasted glass

- Improve the bearing capacity of tempered glass from many aspects

- The importance of building U-shaped glass curtain wall for shading